1. Principles of Laser Processing

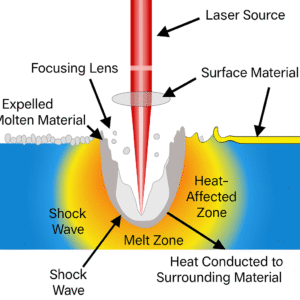

The principle of laser processing is similar to how a convex lens focuses sunlight to ignite a match.

Laser emitted from the source passes through a series of optical elements and is focused by a lens into a very small spot where the energy is highly concentrated.

If the workpiece material absorbs the laser energy effectively, the irradiated area heats up rapidly. Depending on the material’s properties (melting point, boiling point, chemical reaction temperature, etc.), the workpiece undergoes a series of physical or chemical changes, such as:

-

Melting

-

Vaporization

-

Oxidation

-

Discoloration

These changes form the basis of laser processing.

The diagram below shows the interaction between the laser beam and the material during processing:

2. Advantages of Laser Processing

2.1 Advanced Processing Method, High Efficiency

-

The focused laser acts as an “invisible micro-tool,” burning away the material point by point.

-

Non-contact processing, free from mechanical stress or deformation.

-

Very small heat-affected zone and high precision.

-

Enables techniques that are impossible with conventional machining.

2.2 Low Cost, Fully Automated, Easy to Operate

-

The focused laser spot itself is the “tool,” requiring no additional consumables.

-

High speed and low processing cost.

-

Computer-controlled, fully automated operation—supports 24/7 continuous production with minimal human intervention.

2.3 Clear and Permanent Product Identification

-

Laser marking removes surface material, creating permanent marks that do not fade with humidity, acidic/alkaline environments, or abrasion.

-

Unique identifiers such as serial numbers or QR codes can be marked for product traceability.

-

Laser marking is highly resistant to counterfeiting due to its distinctive effect.

2.4 Flexible Production, Zero Inventory Backlog

-

Highly adaptable to varying customer orders.

-

Automatically calculates production quantity and time.

-

Minimizes inconsistent production and reduces risk of stockpiling.

2.5 Environmentally Friendly

-

Non-toxic, pollution-free processing.

-

Products meet European and American environmental standards.

-

Avoids export restrictions caused by traditional methods such as screen printing or chemical etching.